Technical Library

STRUCTURE I: The Soundboard

Entire Contents Copyright © 2011 CBHTechnical LibrarySTRUCTURE I: The Soundboard Entire Contents Copyright © 2011 CBH |

The Soundboard…

The soundboard is the heart of the harpsichord. The softwoods normally used for decent harpsichord soundboards are choose for their tonal properties. The best instruments use the traditional European material Swiss pine

(Picea abies), although many North American makers have used Engelmann spruce (Picea engelmannii) or more commonly Sitka spruce (Picea sitchensis) because of availability. Soundboard wood is normally sawn on the quarter, which means that the visible thin edge of the soundboard at the gap shows distinctive near-vertical alternate early wood and late wood stripes.

Across the grain, spruce is actually stronger than the same weight of steel—although it splits readily along the grain. Compared to the 8–10mm thickness of a modern piano soundboard, that of the historic-style harpsichord is nominally around 3–3.5mm thick and often thinner in the treble corner.

Nothing is more startling to an owner than to suddenly discover the appearance of a soundboard crack. (Or worse—to be awoken in the middle of the night by a loud explosion as the board splits asunder!)

All wood shrinks with moisture loss and age, so it’s not unusual to see older instruments with at least a few hairline cracks. These do not normally affect the tone of the harpsichord, but can look unfortunate.

However, sometimes cracks can be indicative of other troubles with the instrument, either related to failure of the structure to hold the required tension of the strings, or damage in transit.

|

Some harpsichord maker jokingly nicknamed the frequently-seen treble soundboard split as “le crack obligatoire.” A crack doesn’t have to be essential in the treble corner, but commonly happens because the soundboard is held tightly at its treble edge under the cheek moulding, while the tension of the strings pulls the bridge(s) and soundboard towards the front of the instrument. The resultant crack is often right at the very end of the bridge. In many instruments like the example pictured here, a definite step can also be seen at the bellyrail where the soundboard has lost adhesion and crept forward—sometimes enough to interfere with the free operation of the registers and/or jacks. This if often the first indication to the player that anything might be amiss. It’s one thing for the board to crack, but the step in the board at the bellyrail can often be a sign of internal structural problems. Sometimes the curved treble end of the 4´ hitchpinrail underneath the board can be found to have not been installed tightly against the bellyrail to begin with, or perhaps has sheared because of crossgrain. A more involved repair is then called for. Symptoms of related tension problems can include:

|

| Treble soundboard crack with creepage over bellyrail |

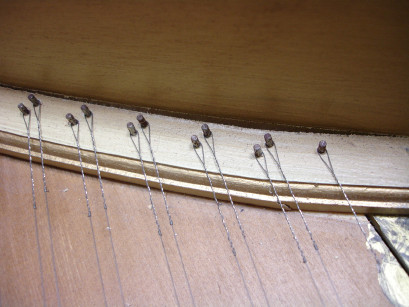

A crack in the extreme treble of the soundboard is often associated with failure of the treble end of the bentside (or 8´) hitchpinrail. It happens in this part of the compass because the tension of the unison strings directly pulls the rail away from the bentside and breaks the glue joint. Further down, failure of the bentside hitchpinrail is less common because the bentside straightens out. A similar failure, though, can often be observed in the tail hitchpinrail in the bass of the instrument, where again the strings pull the rail almost perpendicularly away from the case. When the bentside hitchpinrail fails, the gap between it and the inside face of the bentside is clearly visible. The depth of the gap can be determined by careful insertion of a piece of plastic film strip or even a thin metal ruler. If such a gauge can be inserted to below the level of the soundboard, the failure is more serious and it is obvious that the liner has also pulled away from the bentside. In this example, a split can also be seen in the bentside hitchpinrail itself. Sufficient attention was probably not paid by the maker to the grain direction at the treble end of this important piece. Good treble tuning stability can never be expected in an instrument like this. |

|

| Treble soundboard crack with bentside hitchpinrail failure |

|

Sometimes the sudden shock caused by a drop in transit can break a glue bond and pop the underside supporting furniture off the soundboard. The board then can be suddenly unhinged, and have no choice but to split. Although carefully packed, this particular harpsichord was probably dropped during its transcontinental move, popping the end of the 4´ cutoff bar and causing a crack along the spine near the bass end of the 4´ bridge. The repair of this instrument, requiring a hole in appropriate position in the bottom for hand access, is shown here. A lesser shock can cause more serious damage in an amateur-built instrument where the ends of the ribs may have been left full thickness. It is not uncommon to see a crack running close to the spine for the entire length of the board. If the ribs had been correctly scalloped, their ends can flex somewhat with the board rather than create a huge difference in rigidity right at that point. |

| Crack along the spine with dislodgement of bass end of 4´ cutoff bar |

| Technical Library overview | |

| Harpsichords Australia Home Page |